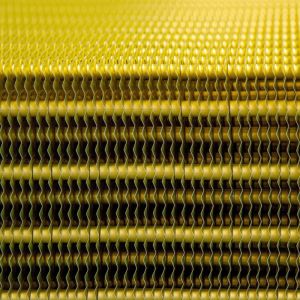

BERGCOLD » Heat exchanger & Dry cooler

Efficient and secure heat dissipation

Our heat exchangers and dry coolers utilize cutting-edge technology to efficiently remove heat from industrial processes. This not only results in significant energy savings but also contributes to reducing operational costs.